Saugus Iron Works

History is littered with stories of people who spotted a market opportunity but then failed as a result of poor implementation. In 1641 John Winthrop the Younger identified the opportunity to establish an ironworks in the colonies. Iron was an essential raw material for goods such as weapons, cookware, nails and horseshoes, but it had to be imported all the way from England. Winthrop believed that there was a major opportunity to establish an ironworks in the colonies, and he found backers in England prepared to put up the money to get it going. In 1644 he selected Braintree in Massachusetts as the site of his foundry. It opened in 1645, but it immediately hit problems - there was no local iron ore and inadequate supplies of water to power the foundry. Winthrop was quickly replaced by Richard Leader who had experience of iron making and in 1646 he moved the foundry to the Saugus River which had water both for power and transport plus forests for making charcoal and supplies of bog ore. The foundry, called the Hammersmith Works, produced several types of iron and also produced finished goods such as cookware. Iron production was not a skill found widely among the Puritans, so skilled workers were brought in from England. The iron works never operated at a profit, largely due to poor financial management but many of the skilled workers were arrested under Puritan laws for crimes such as gambling or drunkenness, which would not have helped. The works closed in 1668 and the site on the Saugus River returned to nature.

DLU171212

Click on Minimap to navigate

Home > US States > New England > Massachusetts > Essex County >

To move forwards or backwards through the Essex County trail click the arrows above, or select your next destination on the Minimap.

Blast Furnace Bellows

The Blast Furnace smelted bog ore into cast iron. Bog ore is a very impure source of iron ore and a very high temperature was required in the smelting process. To reach the necessary temperature, the charcoal had to be burned in a plentiful supply of air. The precise arrangements at the original blast furnace are unknown, but it is likely that huge bellows were uses, similar to the reconstruction shown here.

Water Wheels

Charcoal provided the heat within the iron works while water provided power. The Forge (in the foreground) was where cast iron from the blast furnace was refined into wrought iron by melting it to reduce the level of carbon then hammering it into a block. The Rolling and Slitting Mill (in the distance) is where wrought iron was heated and then passed between rollers to turn it into bars of the required thickness. Some of the bars were also put through the slitting machinery to make rods and nails. The waterwheels that power the forge and mill are functional but are are normally operated only during special events.

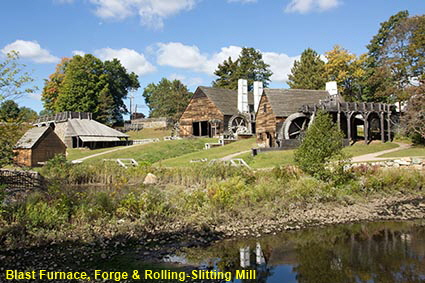

Blast Furnace, Forge & Rolling-Slitting Mill

The reconstructed iron works on the banks of the Saugus River looks pleasant and tranquil, but back in the 1650s this would have been a hive of activity. The blast furnace (on the left in picture, behind wood cabin) would have operated 24 hours a day for periods of many months. The water wheels would have been turning to power machines in the forge and mill. It would have been a very noisy and smoky place to work, and by modern standards very dangerous. The accident rate, particularly amongst the less skilled workers, was very high.

Iron Works House

After the iron works closed, they were forgotten about until in 1898 the Lynn Historical Society placed a marker near the site. In 1917 Wallace Nutting purchased a farm house dating back to the 1680s near the site of the iron works. He restored it and added a blacksmith shop to make and sell reproduction colonial ironwork but he sold the house in 1920. In 1943 the First Iron Works Association (FIWA) purchased the farmhouse and the site of the iron works. Archaeologist Roland W. Robbins began excavation of the ironworks in 1948. He discovered the blast furnace, the foundations of other buildings, a hammer from the forge and even a water wheel. The remains of the earliest iron works in North America had been discovered, and the FIWA decided that it should be reconstructed. The task was given to a Boston firm that had restored Colonial Williamsburg. The restoration was based partly on archaeological evidence, partly on contemporary documentation and partly on guesswork. The reconstructed Saugus Iron Works opened to the public on September 18, 1954. The old farmhouse formed part of the reconstruction, and was named Iron Works House. The site was operated by FIWA and funded by the American Iron and Steel Institute (AISI) but in the early 1960s AISI announced that they could no longer fund the site. In 1968 the site became part of the National Park Service system as Saugus Iron Works National Historic Site. The park is open to the public between April and the beginning of November.

Rolling & Slitting Mill

The archaeological excavation recorded little about the rolling and slitting mill, but there are some records describing the mill which align with 17th and 18th century engravings of mills elsewhere. The reconstruction is based on such engravings. In the reconstruction a huge wooden gear wheel transmits power to rollers (left of centre in the picture) which turn the wrought iron into bars of a set thickness.

© Mike Elsden 1981 - 2025

The contents of this page may not be reproduced in full or in part without permission